dB Engineering Quilted Fiberglass Absorbers are fire safe, high performance acoustical fiberglass blankets that are used to reduce reverberant (reflected) airborne noise energy in many diverse industrial and architectural applications as well as on original equipment.

dB Engineering Quilted Fiberglass Absorbers are fire safe, high performance acoustical fiberglass blankets that are used to reduce reverberant (reflected) airborne noise energy in many diverse industrial and architectural applications as well as on original equipment.

They are available as overhead sound absorption baffles, wall panels, in roll form with edges bound or unbound or as die-cut pieces. An excellent alternative to urethane foams since they are fire safe, exhibit low smoke emissions and possess high mechanical strength. Additionally, they have a wide range of temperature limits, can be cleaned, and are unaffected by moisture, humidity, dust, dirt, oils and most chemicals. Flexible quilted absorbers are easily installed, will not degrade and have extremely long service lives.

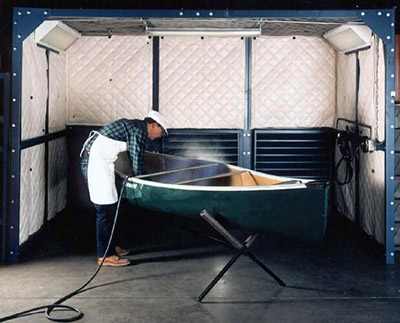

Our White Quilted Fiberglass Absorbers being used at a gun range.

Features

- Superior sound absorption ratings up to NRC 1.05

- Maximum durability, long life span

- Class A flammability rated

- Wide variety of facings, colors, stitch patterns

- Used in Architectural, Commercial, OEM & Industrial applications

Applications

- Ceiling Baffles

- Wall absorbing blankets

- Engine compartments

- Enclosure liners

- Pipe and duct wrap

- Machine housings

Sound Absorption Wall Panels and Overhead Ceiling Baffles

- Reduce reverberation

- Add sound absorption to environment

- Lower noise levels

- Tone room, turn hard reflective surfaces into soft, sound absorptive surfaces

- Improve communication

| Flammability Ratings: | |||

| Model Numbers | Flame Spread | Smoke Density | Class |

| Vinyl-coated-fiberglass-cloth faced: QFA-1, QFA-4, QFA-7 QFA-10, QFA-14, QFA-20 |

17.67 | 22.75 | 1,A |

| Silicone-coated-fiberglass-cloth faced: QFA-2, QFA-5,QFA-8 QFA-11, QFA-16, QFA-22 |

4.95 | 11.43 | 1,A |

| Non-woven porous scrim faced: QFA-3, QFA-9, QFA-18 |

5.07 | .45 | a,A |

| Flammability Testing per ASTM E-84: “Surface Burning Characteristics of Building Materials” | |||

| Acoustical Data: | ||||||||

|

Sound Absorption Data |

Random Incident Sound Absorption |

|||||||

| Model No. | Normal Thickness | 125 | 250 | 500 | 1000 | 2000 | 4000 | NRC |

| QFA-1 | 1 inch | .12 | .47 | .85 | .84 | .64 | .62 | .70 |

| QFA-2 | 1 inch | .04 | .46 | .86 | .81 | .59 | .31 | .70 |

| QFA-4 | 1 inch | .17 | .30 | .83 | .82 | .59 | .37 | .65 |

| QFA-7 | 2 inches | .07 | .27 | .96 | 1.13 | 1.08 | .99 | .85 |

| QFA-10 | 2 inches | .19 | .99 | .96 | .80 | .57 | .33 | .85 |

| QFA-14 | 4 inches | .21 | .89 | 1.09 | 1.17 | 1.13 | 1.07 | 1.05 |

|

Sound Absorption Data |

Absorption Coefficients – Sabin/Unit Octave Band Center Frequencies (HZ) |

|||||||

| Model No. | Dimensions | 125 | 250 | 500 | 1000 | 2000 | 4000 | NRC |

| QFA-4 Baffles | 2′ x 4′, 1″ th | .59 | 2.43 | 7.17 | 8.66 | 8.82 | 6.71 | 6.75 |

| QFA-10 Baffles | 2′ x 4′, 2″ th | .91 | 6.07 | 8.25 | 8.88 | 6.65 | 5.58 | 7.45 |

| Actual Testing Per ASTM C423-77, C423-81, C423-84A, C423-90A | ||||||||

QFA-10 panel wall separates noisy machinery area from an assembly line in automotive parts manufacturer.

| Product Information | ||||

| Model No. | Quilted Fiberglass Absorbers Product Description | Nominal Quilted Thickness | Roll Width | Roll Length |

| QFA-1 | Single layer fiberglass, one side faced with VCFC, opposite side faced with NPS | 1 inch | 48 inches | 50 feet |

| QFA-2 | Single layer fiberglass, one side faced with SCFC, opposite side faced with NPS | 1 inch | 48 inches | 50 feet |

| QFA-3 | Single layer fiberglass, both sides faced with NPS | 1 inch | 48 inches | 50 feet |

| QFA-4 | Single layer fiberglass, both sides faced with VCFC | 1 inch | 48 inches | 50 feet |

| QFA-5 | Single layer fiberglass, both sides faced with SCFC | 1 inch | 48 inches | 50 feet |

| QFA-6 | Single layer fiberglass, one side faced with VCFC, opposite side faced with SCFC | 1 inch | 48 inches | 50 feet |

| QFA-7 | Double layer fiberglass, one side faced with VCFC, opposite side faced with NPS | 2 inches | 48 inches | 25 feet |

| QFA-8 | Double layer fiberglass, one side faced with SCFC, opposite side faced with NPS | 2 inches | 48 inches | 25 feet |

| QFA-9 | Double layer fiberglass, both sides faced with NPS | 2 inches | 48 inches | 25 feet |

| QFA-10 | Double layer fiberglass, both sides faced with VCFC | 2 inches | 48 inches | 25 feet |

| QFA-11 | Double layer fiberglass, both sides faced with SCFC | 2 inches | 48 inches | 25 feet |

| QFA-12 | Double layer fiberglass, one side faced with VCFC, opposite side faced with SCFC | 2 inches | 48 inches | 25 feet |

| QFA-14 | Quadruple layer fiberglass, one side faced with VCFC, opposite side faced with NPS | 4 inches | 48 inches | 25 feet |

| QFA-20 | Quadruple layer fiberglass, both sides faced with VCFC | 4 inches | 48 inches | 25 feet |

| QFA-22 | Quadruple layer fiberglass, both sides faced with SCFC | 4 inches | 48 inches | 25 feet |

|

Table showing how the human ear perceives noise reduction. |

|

| Decibel Reduction | Reduction Experienced by Ear |

| 2 | 15% |

| 4 | 23% |

| 6 | 38% |

| 8 | 48% |

| 10 | 56% |

| 12 | 63% |

| 14 | 68% |

| 16 | 75% |

| 18 | 77% |

| 20 | 81% |