The dB Engineering Lag Series combines a loaded vinyl noise barrier with a fibrous glass scrim reinforced aluminum foil facing on one side. B-10 LAG is commonly used for wrapping noisy iron, steel, and plastic pipe, ducts, valves, and heat exchangers in a wide variety of indoor and outdoor applications. The entire series has excellent corrosion and outdoor weathering resistance, high strength, and excellent conformability. The reinforced foil facing readily ac

The dB Engineering Lag Series combines a loaded vinyl noise barrier with a fibrous glass scrim reinforced aluminum foil facing on one side. B-10 LAG is commonly used for wrapping noisy iron, steel, and plastic pipe, ducts, valves, and heat exchangers in a wide variety of indoor and outdoor applications. The entire series has excellent corrosion and outdoor weathering resistance, high strength, and excellent conformability. The reinforced foil facing readily ac

cepts a matching tape for quick and easy installation.

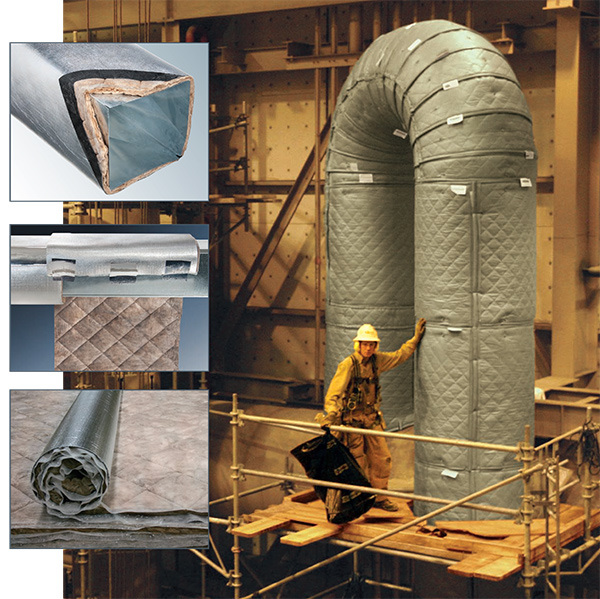

B-10 LAG is available in combination with a nominal one-inch thick (B-10 LAG/QFA-3) or two-inch-thick (B-10 LAG/QFA-9) quilted fiberglass decoupler to form a tight-fitting “floating” noise barrier. The quilt decouples the loaded vinyl barrier from the noise emitting surface achieving greater noise reductions. The one-step installation of decoupler, barrier, and outer jacket offers substantially lower installation costs. The composite combination is also designed to provide thermal insulation to reduce energy consumption.

Barrier Backed composite, a reinforced loaded vinyl noise barrier with a quilted fiberglass absorber on one side

Barrier Backed composite, a reinforced loaded vinyl noise barrier with a quilted fiberglass absorber on one side

Barrier Backed composite.

BBC composite products were used to wrap a pipe at a wastewater treatment facility (shown to the right), resulting in a 15 dB reduction in noise.

Barrier Backed composite

Features

- STC ratings of 26-30

- Easy to cut and install

- Accepts matching tape

- Good corrosion resistance

- High and low temperature applications

- Quilted fiberglass decoupler available

- Meets Class A flammability rating per ASTM E-84

Applications

- Noisy pipes

- Sheet Metal

- Duct work

- Heat exchangers

- Valves

- Custom acoustical jackets

| Acoustical Data: | |||||||

| Products | Sound Transmission Loss (dB) Frequency (Hz) | STC | |||||

| 125 | 250 | 500 | 1000 | 2000 | 4000 | ||

| B-10 LAG | 15 | 16 | 21 | 26 | 33 | 38 | 26 |

| B-10 LAG/QFA-3 | 18 | 18 | 23 | 30 | 39 | 46 | 29 |

| B-10 LAG/QFA-9 | 19 | 20 | 23 | 33 | 44 | 53 | 30 |

| Per ASTM: E90 | |||||||

| Physical Properties of Components | |||||||

| Product | Weight | Thickness | Service Temperature |

Tensil Strength |

Tear Strength | Elongation | “R” Factor |

| Barrier | |||||||

| B-10 LAG | 1 Lb. PSF | .090″ | -10o to + 180oF | 400 PSI | 72 | 40% | – |

| Decoupler/Absorber | |||||||

| QFA-3 | .2 lb. PSF | 1″ Nom | -20o to + 350oF | – | – | – | 4.0 |

| QFA-9 | .4 lb. PSF | 2″ Nom | -20o to + 350oF | – | – | – | 8.0 |

| Flammability Properties | |||||||

| B-10 LAG |

UL94-Meets VO FMVSS-302: Pass |

||||||

| B-10 LAG/QFA-3 |

ASTM E-84 “Surface Burning Characteristics of Building Materials”; |

||||||

| B-10 LAG/QFA-9 | |||||||

|

Table showing how the human ear perceives noise reduction. |

|

| Decibel Reduction | Reduction Experienced by Ear |

| 2 | 15% |

| 4 | 23% |

| 6 | 38% |

| 8 | 48% |

| 10 | 56% |

| 12 | 63% |

| 14 | 68% |

| 16 | 75% |

| 18 | 77% |

| 20 | 81% |