“O.K., we’ll flip for it. Heads I have to do it, tails you have to do it.” Sounds like a conversation between two kids arguing over who has to take out the trash. But in actuality, it was the type of conversation that took place for years at a large plastics manufacturer in the Northeast until they Found our innovative curtain enclosure.

Like other manufacturers, this plastics producer has a certain amount of waste inherent in the making of a product. Fortunately, they are able to recycle waste. Waste is loaded into a granulator that grinds the plastic into tiny pellets. Eventually, these pellets are reused in a finished product. The problem was that no employee wanted to go near the granulator. It was the loudest machine on the shop floor peaking at 110 dB (A).

Finally, the noisy granulator became too much for management to deal with. Complaints from shop employees became more frequent, waste piled up meaning that potential raw materials were being squandered and the threat of an insurance claim or an OSHA violation grew every day. Something had to be done quickly.

Company management figured that the best way to overcome the problem was with some type of acoustical enclosure, either metal or one constructed from composite materials. A metal enclosure would help reduce noise levels once the proposed design provided no protection for the operator when loading the machine. Another disadvantage of the metal enclosure is that access to the machinery would have been limited.

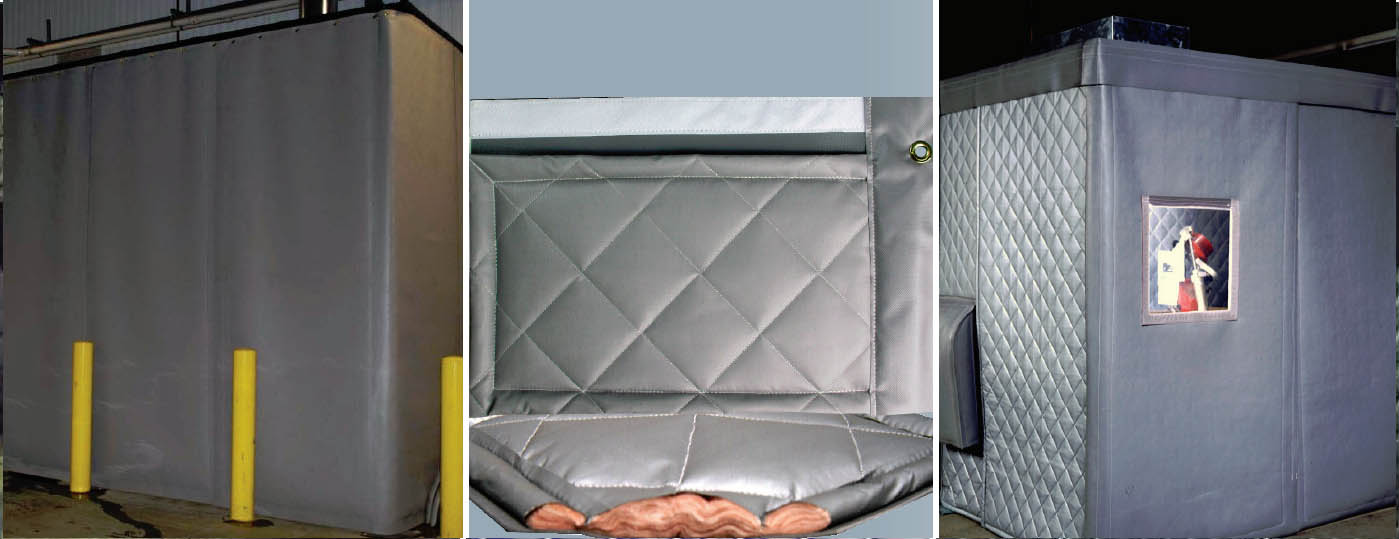

Sound Seal applications engineers offered an enclosure design featuring their BBC-13-2” composite material, a combination sound absorber and noise barrier. The composite is made up of a 1 lb/sq.ft. reinforced loaded vinyl noise barrier and 2” thick quilted fiberglass sound absorber. Typically, a 1” thick absorber is put on the interior of a reinforced barrier. Because of the extreme conditions in this case, Sound Seal engineers utilized the 2” thick material.

The BBC-13-2” composite gives overall noise protection comparable to the metal enclosure and because of Sound Seal’s extensive fabricating capabilities, the enclosure could be customized to meet every specification of the plastics manufacturer.

A critical design feature that Sound Seal engineers developed was a feed flap that gave the operator a substantial amount of protection when loading the granulator. Prior to the installation of Sound Seal’s enclosure, the operator was subjected to 110 dB(A) of noise at close range. Continuous loading of the granulator without hearing protection would have been disastrous. With the new enclosure featuring the feed flap, an operator no longer needs hearing protection.

Engineers also overcame the concern the company had about access to the machine. The double curtain track and hardware design allows access at any point in the enclosure. Another key design feature is the ventilation system. Too often, the installation of a roof panel means sacrificing ventilation for enhanced acoustical performance. The idea of “one-stop shopping” at Sound Seal also appealed to the plastics manufacturer. Many noise control companies only sell the materials which comprise the enclosure. These companies leave it to the customer to find someone who can provide the structural framework for the enclosure and handle the installation. Sound Seal has its own line of free-standing or suspended structural support systems, and an installation team. In fact, this enclosure was installed in just four hours. Employee response to the enclosure has been tremendous. Loading and running the granulator is no longer the dreaded task it once was. Consequently, waste no longer piles up and materials are quickly recycled. The granulator is finally the productive machine management always hoped it would be.

ACOUSTICAL PERFORMANCE

| SOUND TRANSMISSION LOSS

Octave Band Center Frequency (Hz) |

||||||||

| Location | A | 125 | 250 | 500 | 1000 | 2000 | 4000 | 8000 |

| BEFORE at operator | 110 | 96 | 99 | 102 | 104 | 109 | 96 | 90 |

| AFTER at operator (feed hatch closed) | 88 | 90 | 91 | 89 | 83 | 79 | 73 | 70 |