Ford Motor Company Plant | Dearborn, Michigan

Squealing tires and screeching brakes, loud distracting noises, which are usually associated with a race track or cross-town travel. Not in this case, however. Inside a Ford Motor Company assembly plant, employees in the Roll Test Operation Department jump into a shiny new Ford fresh off the assembly line, accelerate to 60 MPH and then stomp on the brakes. This is the first step in testing acceleration and braking on new vehicles fresh off the assembly line, which are then moved to an idle lane for additional tests.

Ford Motor Company’s policy of creating and maintaining high standards of employee comfort and benefits led to a desire to reduce the noise level exposure for workers in the surrounding area. Company management called in an acoustical consulting firm familiar with Sound Seal’s products and systems and fabrication capabilities,with an understanding that design flexibility, creativity and customer service were as important as product performance and economy.

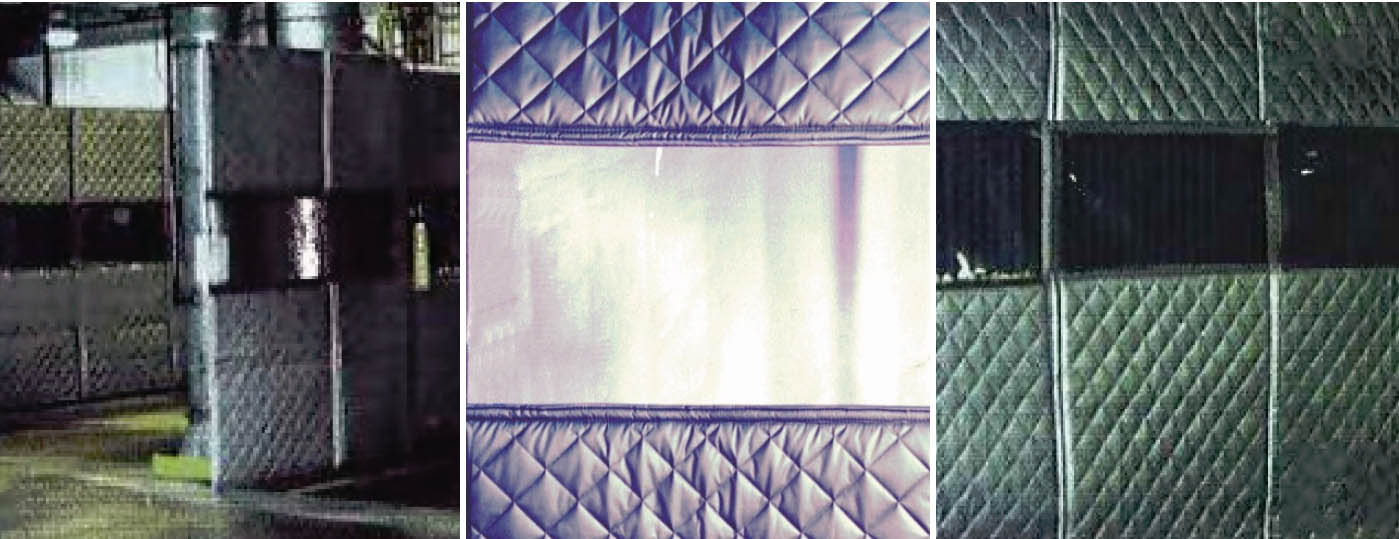

After extensive testing and analysis, the acoustical engineers selected noise control products we offer expertise in flexible noise control materials, products and systems. As opposed to some of the rigid, metal panel type of noise control products available in the marketplace, flexible sound absorber/noise barrier composite products can offer maximum accessibility, visibility and affordability, while still offering significant noise reduction. The consultants recommended utilizing Sound Seal acoustical products to create three forty-foot long bays to separate the idle lane from the active lanes. The Sound Seal Acoustical Curtain Panel model BSC-25 combines a quilted fiberglass sound absorber on both sides of a loaded vinyl noise barrier. The modular curtain panels were fabricated with full-width view windows, grommets at the top with hook and loop fasteners along each edge to join adjacent panels together to form the designed configuration. The BSC/full-width view window panels are specifically designed to offer complete visibility into the area along with effective sound absorption and noise barrier characteristics.

The BSC-25 Acoustical Composite Curtain Panels satisfied the acoustical engineer’s requirements to provide separator partition walls between each bay by utilizing a single product that would serve as both a noise barrier material between bays as well as a sound absorption product within each bay. In general, ASTM laboratory testing standards are utilized to determine how effective various products perform regarding their ability to either absorb sound waves, rated as “NRG”, or block sound waves, rated as “STC”. The NRG (Noise Reduction Rating) of BSC-25 is .85. The STC (Sound Transmission Classification) is 29. Since a heavy-duty one pound per sq.ft.flexible transparent vinyl noise barrier material is utilized as the view window section of the panels, there is minimal, if any, loss of acoustical performance thru the window area.

An Acoustical Curtain Panel, BBC-13-2″, was used as an “end cap” on one end of the bays. Its purpose was also to contain and absorb the noise. However, since these panels are in a potential high abuse area where they drive the cars and move other equipment into the bays, the BBC-13-2″ Acoustical Curtain Panels are utilized because they have a very rugged, durable reinforced noise barrier exterior and the quilted fiberglass sound absorber on the interior side only.

Even with large open areas and an open-top, upon completion of the Acoustical Curtain Enclosure, employees’ noise exposure dropped by 8 dB (A) bringing these employees within acceptable noise exposure limits and creating a better working environment for Ford Motor Company’s valued employees.

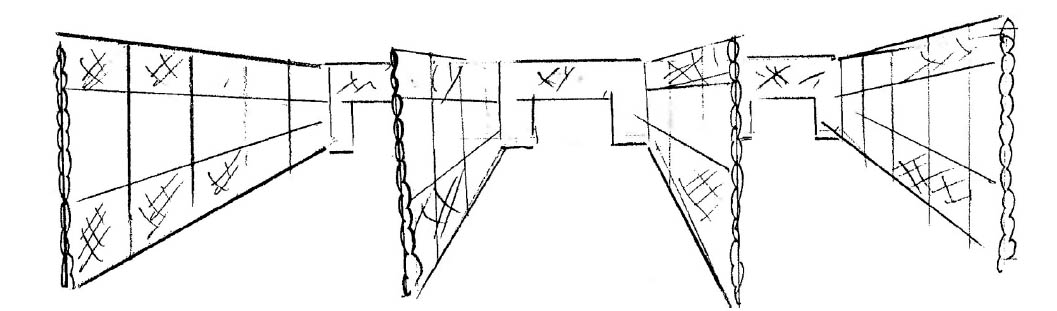

Conceptual drawing of three-bay acoustical curtain systems designed by acoustical consultant and manufactured by Sound Seal.

Sound Seal’s BSC-25 acoustical curtain panels with full-width clear vinyl view windows form a three-bay acoustical curtain enclosure at a Ford Motor Company plant.